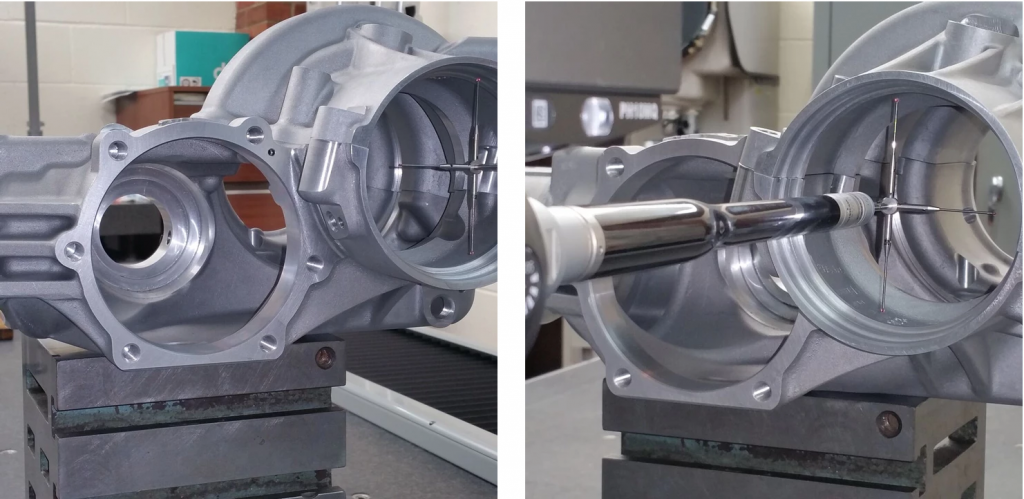

On the 14th September we took a call from one of our high end automotive customer. They were having problems in the testing of a rear axle we had previously manufactured. The issue was design/ strength, so they needed a new “beefed up” axle to test for the 1st October.

A project like this would normally take 8/10 weeks as we would arrange meetings with our customer, offer design for manufacture to take cost out, casting/tooling readiness etc. etc. etc.

We had 17 days…

Working closely with our customer, and working 24/7 the customer picked up their new axle onFriday 30th September at 10.00am.

”We work as a team to deliver success; you do not just get one of us, you get all of us.”